Meet some of our clients and the work we’ve done

They’ve accelerated their performance with new ways of working

Capital Delivery: Food/Beverage Manufacturing

Delivering Juice Certainty

With a global supply network and a portfolio of branded and customer own brand products, Princes is one of Europe's largest food and drink groups.

www.princesgroup.com

What was needed:

The Cardiff Juice Centre of Excellence is Princes Group's largest-ever investment in soft drinks. The project will enable the Cardiff site to produce ambient, mini & chilled drinks, doubling the current capacity.

The project involved building a new factory, processing equipment, six lines and warehouse facilities.

The Covid-19 pandemic, supply chain issues & breakdowns in team performance presented a challenge for Princes. They needed a way of working that would overcome these challenges & deliver the investment without any further delays.

What we did:

We implemented our Cadence™ system to increase productivity on the project.

We ensured the right things were done at the right time in the right way.

We built a simple way to govern the project freeing people to focus on value-added contributions and ensuring we had the bandwidth to deal with project complexities.

We implemented Cadence™ by adopting the role as Programme Lead, taking on the responsibility for the entire project delivery as well as showcasing how capital delivery projects should be led within Princes.

The results:

On-time delivery of Key Deliverables

Risk mitigation of further schedule delays and spend

Early adoption of site ownership

Enhanced ability to deliver the next phase of "Stabilisation."

Increased group capability of delivering large capital projects.

Construction:

Kier slashes ten days from an already ambitious programme of works.

Kier is a leading UK construction and infrastructure services company www.kier.co.uk

What was needed:

A critical flood defence programme protecting a residential area was delayed by a variety of factors. The residential area was at risk of flooding again at Christmas should works not be completed. An accelerated programme was produced to meet the critical deadline. No float was including in any activities, very ambitious for tunnelling works. The challenge was to deliver this ambitious programme. Something had to change with the way the team were thinking, behaving and their ways of working.

We found the team:

Needed to act on good ideas they were having

Needed focus, knowing the right work to do

Needed to gain back control and momentum

What we did:

Within 1 day we set up a new way of working to address our findings. Then provided follow up sessions to optimise. Here’s what we did:

Weekly activities were broken down into daily increments.

Daily Planned activities vs Actuals activities were tracked visually.

Daily standups were held to discuss what was working well, and where the issues were.

Basic problem solving - to drill down into the cause of off-track items and to understand winning moves.

Performance Dialogue - Ideas shared by the team members closest to the work and acted on with clear accountability.

The Results:

Beyond possible - The team delivered the programme ten days early despite key stakeholders believing it wasn't possible. A testament to the dedication of all the team involved, as well as the system of Short Interval Control which ensured their efforts were focused and structured.

A dry Christmas - when focused so much on the project and the engineering involved, the bigger purpose is often lost. The effort of this team ensured that the local residents could look forward to a Christmas where they wouldn’t be affected by flooding. Thousands of families enjoying what we all take for granted, because of the efforts of teams like this one.

Manufacturing:

Improved Productivity by 26% at Bedmax

Bedmax is the manufacturer of pedigree equine products

What was needed:

Heavy reliance on key experts was shown to be a risk at a particular site that had a change of personnel. Lack of systems and best practice hindered the site and the wider manufacturing division from building on the great work they were already doing.

What we did:

We built a system of working that focused on excellence across the three manufacturing sites. Building a foundation of an organised workplace, reliable plant & equipment and a capable leadership team.

We scaled the approach from making one theme a habit before moving on and scaling it across the sites, combining lean practices with leadership development and executive coaching.

The Results:

The business was able to increase productivity by 26% and significantly reduce downtime. It was able to respond to customers need and manage the seasonality of its products.

“Aaron is a gifted communicator and understands the process of introducing such a concept. This he has done very successfully by selecting and educating champions of OPEX in our three factories. It is a long process and he has kept us going throughout the three years. But the results are obvious for all to see. Now the factories and the accounts have a much better appearance and outlook than they did before”

Tim Smalley, Managing Director, Bedmax Ltd

Construction:

Building a culture of technical excellence that delivers

TSP Projects now part of the Systra. Systra is a consulting and engineering firm, a world leader in transport infrastructure.

What was needed:

A shift in thinking and ways of working were required to transform a technically focused business to one of technical excellence and project excellence. What was needed was a system to overcome:

The ambiguity of lines of communication between disciplines

Lack of robust feedback mechanism to the project services team

Little transparency between teams of the progress and interdependencies at a daily level

Lack of understanding of critical issues and what was being done about them

Interruptions in the workflow, which were consuming planned buffers

What we did:

We ran a series of pilot projects and built an internal capability of champions to scale an agile workflow approach, optimising visual management and a Kanban process.

Starting with an analogue process using post-it notes and whiteboards, we built the mindset and behaviours to manage the work in shorter intervals, increasing transparency of progress and improving communications between disciplines.

We then moved to a digital version trialing with Trello, before scaling with the use of Office 365 Plan and utilising one note for all the project documentation.

Routines were set up for each discipline and the project services teams, which drove accountability and learning.

Results:

The transformation is still being rolled out by the internal champions. What we have seen, across all project measures, is teams who have already adopted the system are more successful than the teams who haven't started yet. Some examples:

Delivering projects faster

Projects are in control - Scheduled performance (SPI) and cost performance (CPI) are fully understood

Increased client satisfaction

Throughput volume of design in some disciplines doubled, with same resources utilised.

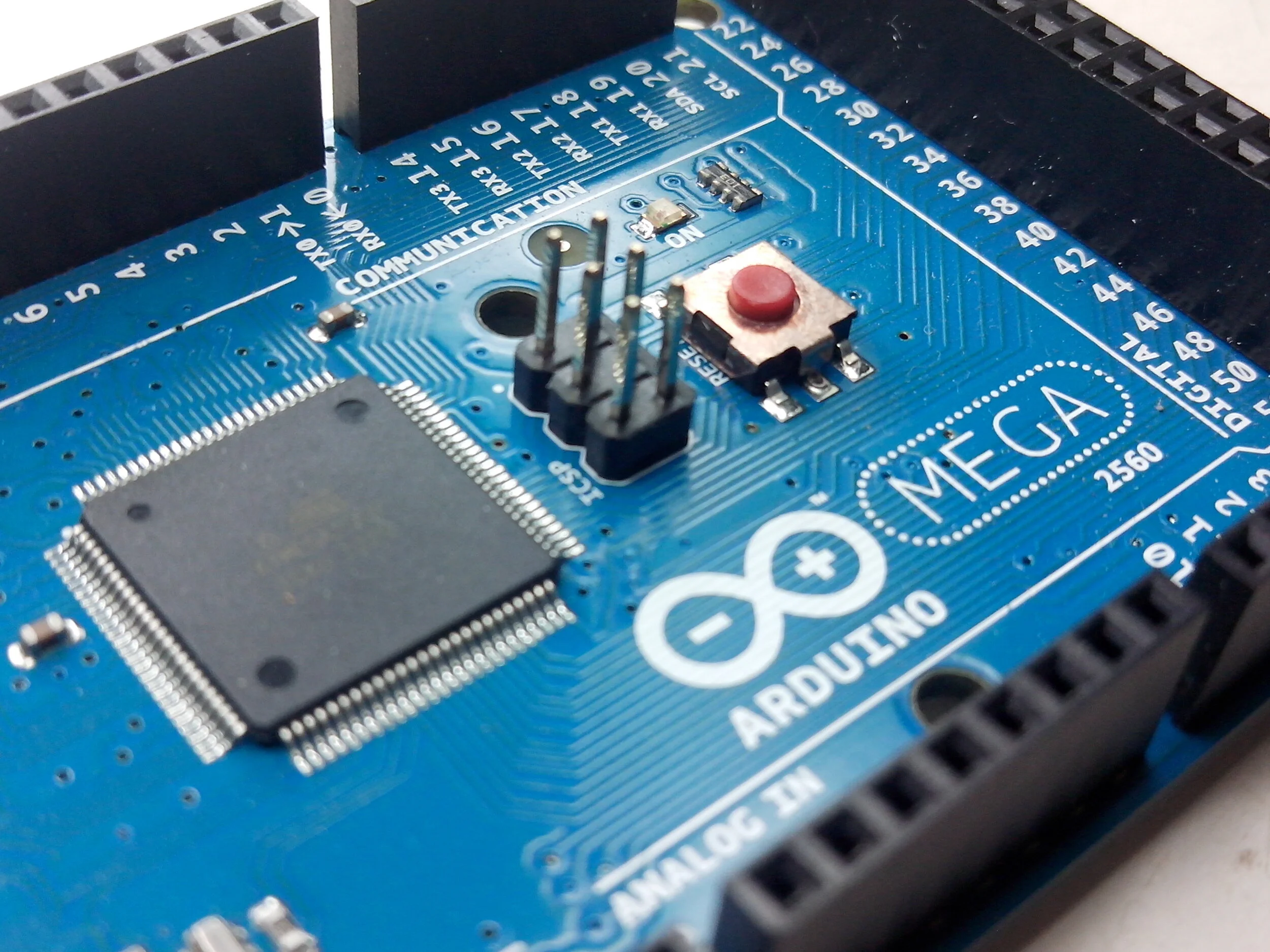

Electronics:

Helping shape the internet of things

We worked with a UK based manufacturer who produce connectivity solutions for industrial applications including automation, robotics, security, asset tracking and smart home technologies.

What was needed:

A merging of two sites required various work cells to be relocated into a reduced footprint. Higher demand for existing products meant an increase in productivity was needed. New products were also being introduced requiring much smaller batches to be delivered a lot quicker, impacting the production of the existing products.

Our findings found:

Current work cells were laid out efficiently to do the work but inefficient upstream and downstream of that cell.

Each work cell had their own feast and famine, in terms of planned throughput of work.

Each cells team members had great ideas however not acted on in the past

What we did:

Over six weeks in 4-day sprints, we delivered a Kaizen based workshop to the experts in the cells. Sharing insights of Lean thinking, then applying it directly into the work areas. We:

Developed lean thinking within each work cell

Reduced non-value added activities within the cell

Balanced the workload in each cell with set limits for work in progress

Organised the cells in the most efficient manner mindful of the value stream

Results:

14.6% reduced costs

41.9% reduction in lead times

48% of floor space reduction

15% improvement in quality

Balanced the flow of work

Improved engagement of staff

Manufacturing:

300 Years in the making

Portals Papers have been making banknote and security paper for the world's leading security printers for over three hundred years.

What was needed:

We were asked to help an executive leadership team of a newly formed business to create a cultural intent. An intent that would create a culture that would enable the business to improve its performance; make it a great place to work; and delight its customers. The company was part of a recent sale of a strategic business unit for a prestigious FTSE organisation. This business unit has a history spanning 300 years. The challenge for the business at this time was to execute its business plan to satisfy the investors and set up the organisation for the future.

What we did:

We designed and delivered a series of workshops to define the desired culture and to build the traction to create it. The programme consisted of a two-day off-site workshop with the Exec team to determine the company culture, company values and expected behaviours. Another workshop then followed it with the Exec team and their direct reports. This workshop consisted of looking at the defined culture and comparing it to the current culture. Amplifiers and inhibitors were identified, and actions put in place to leverage/deal with them. Further site visits kept the traction on the actions.

Results:

Clarity of whom the business wants to become.

The certainty of what the business needs to focus on.

Specific behaviours defined, giving everyone the chance to meet expectations.

Strengthening of the Exec team and their direct reports

Greater Internal commitment and engagement

Culture Fit model that can be used to attract and retain talent.

“I have had the pleasure of working with Aaron from Lean Practice Ltd several times over the past years, most recently on the creation of our new company culture. Aaron always provides credible insight and challenges thought processes to make us think differently and ensure that we be the best we can be. Aaron makes it his business to get under the skin of the organisation, engaging with the workforce to really understand what is needed. I see Aaron and the Lean Practice Ltd as more than consultants – they are a trusted partners who show they care about our success every bit as much as we do. They are dedicated, trustworthy, approachable and a joy to work with. I will certainly be working with Aaron and the team in the future and would have no hesitation in recommending his services”

Alison Longbottom, HR Director, Portals Paper

Rail:

Helping 500 million commuters get to work and get home on time

Delivery certainty with Kier Rail at Redhill Station -Signal renewals and alterations

What was needed:

Pressures of a tight programme of works, delays in materials, and other factors were causing dysfunctions in the team. Their performance and thus, the performance of the whole project was at risk. The team had an opportunity to gain back control and be the examples to the other contractors in the "Hub" and "spoke" arrangement. We were asked to:

Engage the team in displaying the right behaviours for the good of the project

Create a process that creates clarity around project status

Drive ownership at the appropriate party to resolve issues on time

What we did:

Through a series of interventions over 5 days spread over three weeks, we delivered the Lean practice of Short Interval Control which

Exposed dysfunctions in the team and put in actions to overcome them.

Put in place visual management that created "one truth" of the project, with a high-level project on a page report.

Set up daily routines that got the right people in a room at the right time to discuss the real issues.

Created insights to change conditioned thinking that was impacting behaviour and the team's productivity

Improved accountability in team member roles

The intervention was designed by modifying current practices, removing the additional workload and the amount of change required.

Results:

The 10 Day blockade was a success with the first train departing the new platform as scheduled at 05:03 on Tuesday 2nd January 2018. A fantastic effort by all involved.

Short interval Control created:

Increased confidence by the client (Network Rail)

Improved support from the Kier Leadership to the Redhill project team

Improved project performance and management of critical inputs

Improved working environment

Reduced stress levels

A better way to manage their next project